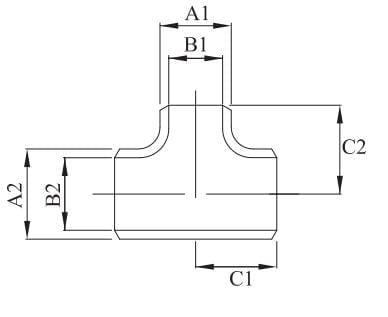

Buttweld Reducing Tee

Efficient Flow Control. Compact Integration. Engineered for Versatility.

The Buttweld Reducing Tee is a critical piping component designed to merge or split fluid flow efficiently while accommodating a reduction in pipe size. Its design features a branch outlet that is smaller than the main run, promoting smooth transitions in flow and improving hydraulic performance in complex piping systems.

At Valve Warehouse Australia, our Reducing Tees are manufactured from premium carbon alloy steel and conform to ASTM A234 standards. These tees are ideal for high-pressure, high-temperature applications across a broad range of industries where durable, welded connections are required for reliable system performance.

Sizing

All sizing is based on Nominal Bore (NB), a standardised measurement referencing the internal diameter of pipes. NB sizing allows seamless compatibility with valves, fittings, and other piping components used in industrial and commercial systems.

Applications and Suitability

Buttweld Reducing Tees are essential in systems that require pipe size transitions while maintaining consistent and efficient flow. Their streamlined design reduces flow turbulence and supports system stability in sectors such as:

- Oil & Gas.

- Plumbing and HVAC.

- Irrigation Systems.

- Power Generation.

- Wastewater Management.

- Industrial Manufacturing.

Technical Advantages

- Welded Integrity: Leakproof, high-strength connection ideal for high-pressure applications.

- Compact Footprint: Suitable for space-restricted installations.

- Smooth Flow Path: Minimises pressure loss and turbulence.

- Corrosion Resistance: Carbon alloy steel construction ensures durability and long service life.

- Versatile Functionality: Supports both branching and reducing flow in a single fitting.

With its durable construction, precise sizing, and efficient design, the Buttweld Reducing Tee from Valve Warehouse Australia delivers superior flow control, structural strength, and long-term reliability. It’s a smart choice for any system requiring dependable pipe size transitions and consistent performance under pressure.

Reviews

There are no reviews yet.